Effective management of groundwater and surface inflow is crucial for open-pit mining operations, especially in areas like Pakistan that are prone to heavy rainfall and monsoon conditions. In these environments, it is essential to continuously monitor water inflow from sources such as rainfall, seepage, and intersecting aquifers to ensure safe and efficient coal mining operations.

Site Conditions and the Need for Automation

The open-pit coal mine under study experiences significant water inflow from two aquifers as excavation progresses below their levels. Seepage and infiltration continuously introduce groundwater into the pit, while seasonal monsoon rains further intensify the problem, leading to rapid water accumulation. To ensure uninterrupted operations, heavy-duty dewatering pumps are deployed to maintain the pit’s stability and accessibility.

However, during the monsoon season, access to the site is often impossible due to flooding and safety concerns, which makes manual water level measurements unfeasible. Consequently, the client required an automated remote monitoring system that could provide real-time data on water level, temperature, and conductivity (LTC) from the pit. This system would enable management to make timely decisions regarding dewatering operations.

Solinst Integrated Monitoring Solution

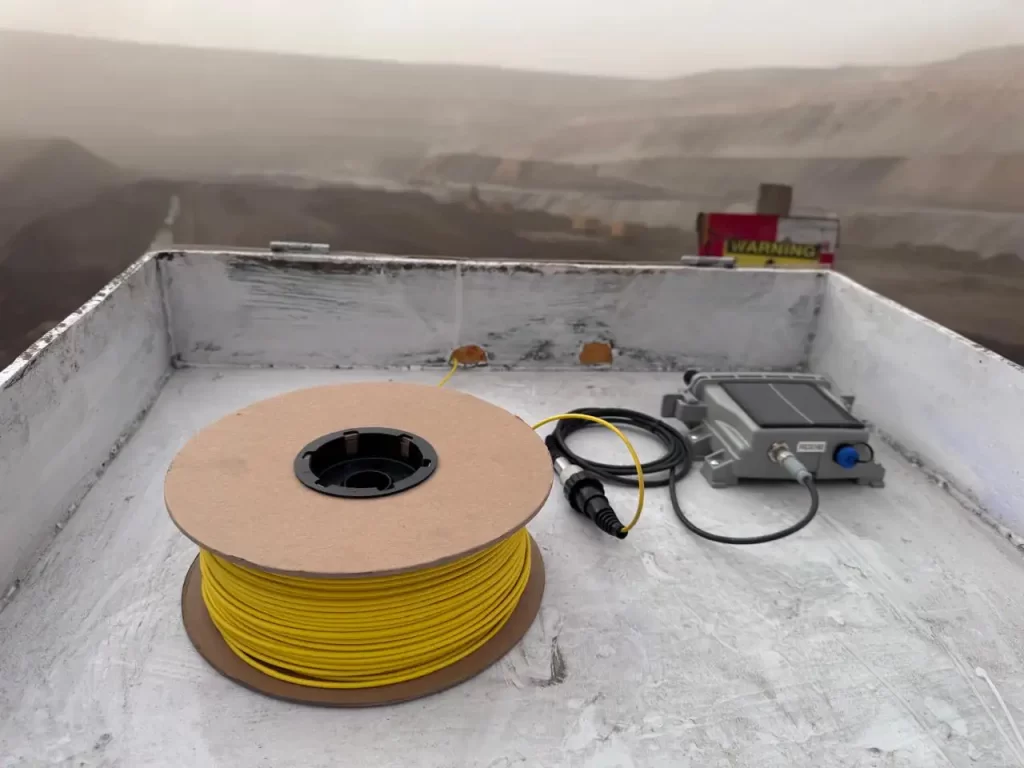

To meet this challenge, a remote monitoring solution was implemented, consisting of:

Levelogger 5 LTC: a high-accuracy water level, temperature, and conductivity logger designed for long-term submersible operation. The Levelogger 5 LTC provides precise measurements of water-level fluctuations caused by rainfall, seepage, and aquifer inflow, enabling continuous hydrogeological assessment of pit conditions.

SolSat 5 Satellite Telemetry System: a compact and energy-efficient satellite data telemetry unit that transmits the Levelogger’s data in near real-time via the Iridium satellite network. The SolSat 5 is ideal for remote, harsh environments such as open-pit mines, where cellular or internet connectivity is limited or unavailable.

SolSat Web Portal: a web-based data management platform that provides instant access to water level, temperature and conductivity data from anywhere (with a web browser). The system enables mine management to visualize live data, generate automated alerts, and analyze long-term trends to optimize pumping operations.

System Functionality and Benefits

Once installed, the Levelogger 5 LTC continuously records water level, temperature, and conductivity at user-defined intervals. The SolSat 5 telemetry unit collects this data and transmits it automatically to the SolSat Web Portal, ensuring uninterrupted data availability even during adverse weather conditions.

This real-time monitoring system provides several key benefits for mine management:

Automated Real-Time Monitoring: Provides live updates on water table levels and inflow conditions without the need for personnel to enter the pit.

Operational Decision Support: Managers can assess trends in water levels and decide remotely whether to increase or decrease pumping rates.

Enhanced Safety: Eliminates the need for manual data collection in hazardous conditions, particularly during the monsoon season.

Reliable Data Transmission: Satellite telemetry ensures connectivity in remote mining areas lacking GSM or internet coverage.

Long-Term Record Keeping: Continuous data logging supports hydrogeological modelling and helps predict seasonal water inflow patterns.

Reliable Water Management in Harsh Mining Environments

The integrated use of the Levelogger 5 LTC, SolSat 5 Satellite Telemetry System, and SolSat Web Portal provides a robust, automated water level monitoring solution for open-pit mining operations in Pakistan. This system delivers reliable, live, and accurate groundwater and inflow data, empowering management to make informed decisions on dewatering operations, especially during monsoon seasons.

By implementing this advanced Solinst monitoring system, mining operators can improve operational efficiency, reduce downtime, and maintain safer working conditions even under challenging hydrological conditions.

Solinst thanks Muzammil Sanghani of Al Ghazi Group of Companies, Solinst Exclusive Distributor in Pakistan, for providing the details of this project.