Reverse Head Profile Datasheet

Depth Discrete Groundwater Monitoring

Reduce Costs and Field Time

Reverse Head Profile

Model 405

The Reverse Head Profile is a technique developed by Solinst Flute for measuring the vertical head distribution in a borehole.

This technique offers a quick and cost-effective way to gather information from previously measured water-producing zones. Hydraulic heads in each zone are estimated while also identifying any potential for cross-contamination between them. The measurements can typically be completed in a day or less within a standard borehole.

How Does the Reverse Head Profile Work?

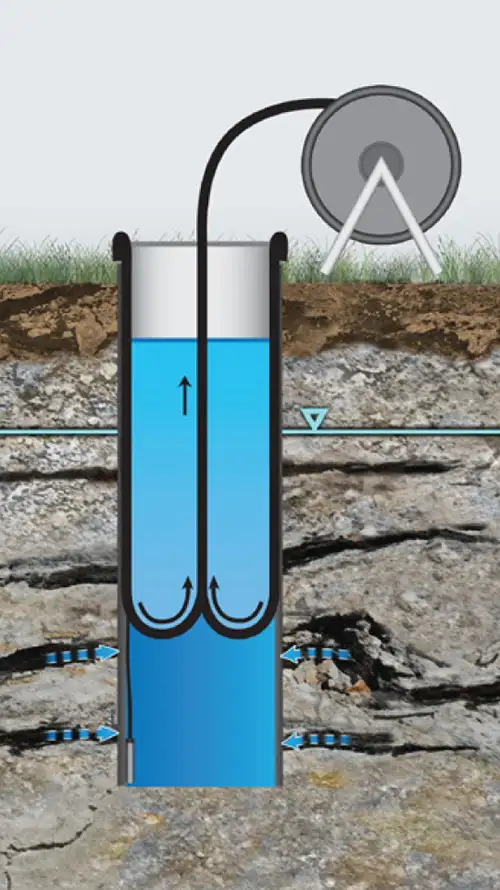

The procedure involves two main steps: the installation (eversion) of a Solinst Flute Blank Liner into an open borehole and the subsequent removal (inversion) of the same liner. The Solinst Flute Blank Liner is designed to seal open boreholes. See the Model 405 Blank Liner Data Sheet for more information.

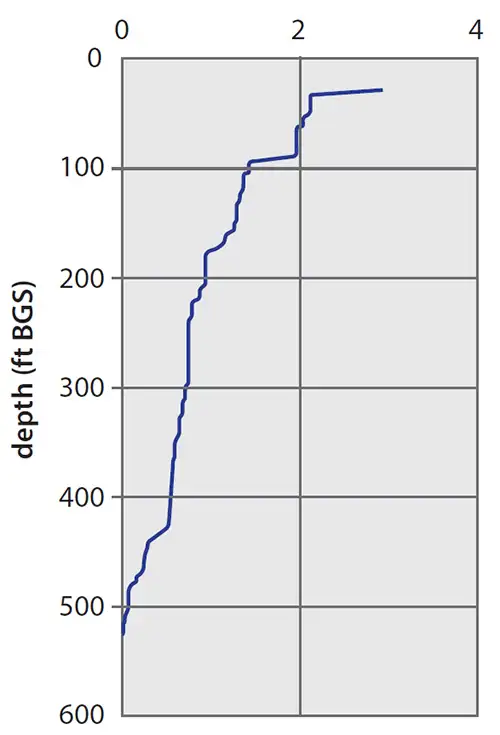

During eversion, a Transmissivity Profile is created, which is described in the Solinst Flute Model 405 Transmissivity Profiling Data Sheet. Transmissivity Profiling rapidly measures all significant flow paths in a borehole.

The Reverse Head Profile method uses a stepwise inversion of the liner to calculate the head at each water-producing zone. As the liner’s inversion uncovers each section of the borehole, the hydraulic head beneath the liner, measured by a transducer at the bottom of the borehole, is allowed to equilibrate. The individual hydraulic heads contributing to each measurement are derived from the measured transmissivity of each zone.

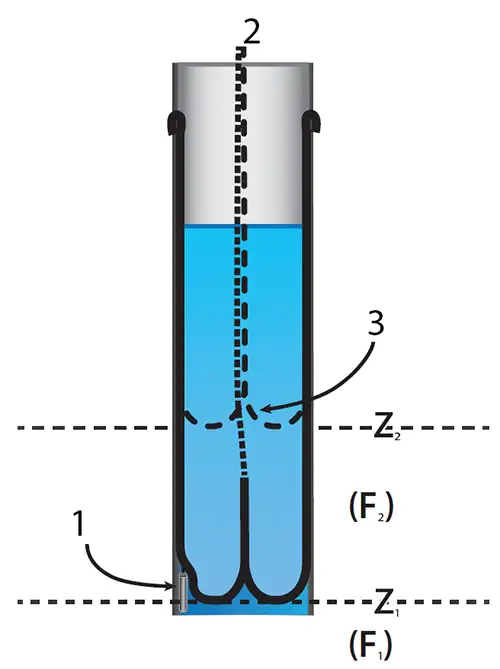

The inversion process:

The liner stops at Z1. The first inversion uncovers a segment of the borehole wall from Z1 to Z2.

- Transducer

- Tether

- Liner inverted to uncover borehole wall

Calculating the Head Profile

As the Solinst Flute Blank Liner is inverted from the well, uncovers discrete borehole intervals of interest that were sealed during the Transmissivity Profile. A pressure transducer located beneath the liner in the borehole records the new steady state borehole equilibrium pressure, Bhi, after each interval is

uncovered.

As we already know the transmissivity of each interval and the previous steady state borehole equilibrium pressure, we can calculate the contribution of the newly uncovered borehole interval by using each new “blended head” beneath the liner and writing the flow equations for each increment that has been uncovered.

We define the net flow into and out of the hole to be zero, and using the transmissivity, Ti, measured for each increment in the hole, one has only the formation head, FH as an unknown for each newly exposed interval of the hole.

For the first open borehole interval beneath the liner: T1(Bh1-FH1) = 0

Hence the formation head, FH1, equals the blended head, Bh1, in the borehole. The transmissivity for each interval, Ti, is obtained from the continuous transmissivity integral (Figure 3).

Upon inverting the liner to uncover a second increment of the

borehole:

T1(Bh2-FH1) + T2(Bh2-FH2) = 0

Solving for FH2,

FH2 = [ T1(Bh2-FH1) + T2 Bh2 ]/T2

Note:

For each new position, a new blended head, Bhi, is measured.

The equation for solution of the formation head of the current interval, i, is:

FHi = [ T1(Bhi-FH1) + T2(Bhi-FH2) + ……. +Ti Bhi ]/Ti

Where Ti is the transmissivity of the ith interval in the hole determined from the liner continuous transmissivity profile, FHi is the calculated formation head of the ith interval, and Bhi is the blended head measured in the borehole after each new ith interval is uncovered. Watching the transducer measurement beneath the liner allows one to judge when a steady-state head has been achieved beneath the liner.

Reverse Head Profile Results

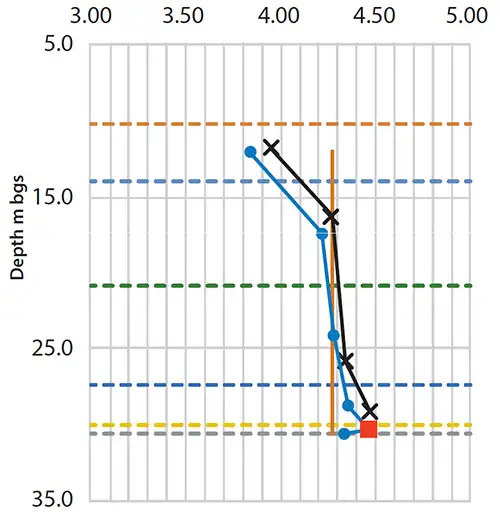

Comparison of RHP to measured

head profile on same day

Water table in each interval (m bgs)

Two Reverse Head Profiles conducted for a 30-Meter Borehole. The blue dots were measured from the 1st RHP values, while the black dots were measured during the 2nd RHP. Note that the vertical red line is the original blended head in the borehole and the red plot point at 30-Meters BGS denotes a measurement taken in a very low transmissive zone and therefore is a less reliable head calculation.

Related Products

Enhanced Bioremediation

The Waterloo Emitter™is a simple, low cost device designed for the bioremediation of contaminated groundwater. It enables oxygen or other amendments to diffuse through silicone or LDPE tubing in a controlled, uniform manner. Ideal for aerobic bioremediation of MTBE and BTEX, with minimal maintenance required.

3/8" Diameter Flexible Pneumatic Pump

The Micro Double Valve Pump has a remarkably small and flexible design. At 3/8" (10 mm) diameter it is small enough to sample groundwater from channels of a CMT System.

Rugged Peristaltic Pump

Compact, lightweight, and water-resistant, the Solinst Peristaltic Pump is designed for field use. One easy-access control allows various speeds and reversible flow. Ideal for shallow water and vapor sampling.

Tag Line - Rugged, Simple, Convenient

The Tag Line uses a weight attached to laser marked cable, mounted on a sturdy reel. Convenient for measuring depths during monitoring well construction.