405 NAPL Flute Datasheet

Depth Discrete Groundwater Monitoring

Reduce Costs and Field Time

Solinst NAPL Flute

Model 405

The Solinst Model 405 NAPL Flute system is a reactive cover for the Flute Blank Liner. The NAPL Flute identifies the location of NAPL (Non-Aqueous Phase Liquids) free product within a subsurface formation, allowing contaminant distribution to be mapped in the pure phase.

The Solinst Flute Blank Liner is a fully removable solution designed to seal open boreholes to prevent cross-contamination.

They can be installed in through eversion in open bedrock, as well as the overburden in cased holes. For more information on Flute Blank Liners and their installation, see the Model 405 Blank Liner Data Sheet.

How Does the NAPL Flute Work?

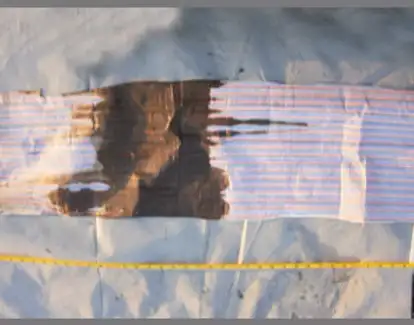

The NAPL Flute everts into a borehole on the outside of a Flute Blank Liner. The NAPL Flute is hydrophobic. It quickly wicks any NAPL contacted in the fractures or pore space into the cover. When the free product contacts the interior of the NAPL Flute, it creates a stain on the cover and dissolves the multicoloured dye stripes.

After a short period, the NAPL Flute and blank liner are removed from the well, and the depth of the free product is determined by measuring the stain depth with a tape measure.

Pre-Installation NAPL Detection

Solinst offers the Model 122 Interface Meter which may be used to help map LNAPL and DNAPL layers in a well or borehole before installing a Blank Liner and NAPL Flute.

The Interface Meter measures water and product level and thickness, accurately to 1.0 mm or 1/200 ft. It uses a 16 mm (5/8”) diameter pressure-proof probe. Readings are read from accurate laser-marked flat tape up to 300 m (1000 ft).

NAPL Flute Installation

Eversion into Boreholes

The NAPL Flute is everted into the borehole on the outside of a Blank Flute Liner.

Direct Push Installation:

The NAPL Flute is compression-wrapped and installed within direct push rods once the terminal depth is reached. The NAPL Flute has a tube for water addition, and as water is added to the interior of the liner, the rods are removed in a stepwise fashion. A tether at the surface allows you to pull the liner out of the hole once the reaction time has finished.

NAPL Flute Reactions with Different Contaminants

Different contaminants react differently with the dye stripes on the outside of the NAPL Flute. Contact with NAPLs such as TCE and PCE dissolves the dye stripes. The cover material is white, and the displacement of the dye is to the interior surface of the cover. That stain indicates that the cover has come in contact with a NAPL. The stain’s size and location indicate the amount of NAPL present and the nature of the source.

Some NAPL materials, such as coal tar and creosote, are naturally dark-coloured. When those materials are wicked into the covering, a dark stain appears on the cover’s inside and outside surface. Other NAPLs, such as gasoline and similarly less aggressive solvents, will also displace the dye stripes to the inside of the thin cover. NAPLs, such as coal oil, do not displace the dye stripes. However, when absorbed by the cover material, those NAPLs produce a translucent cover

appearance, much like an oil stain on paper. The cover does not absorb water.

The cover only reacts to the pure product of the NAPL and does not provide a significant stain if exposed to the dissolved phase.

Mapping the Dissolved Phase

Solinst Flute has a technique called FACT (Flute Activated Carbon Technique) which responds to the dissolved phase of many contaminants. A common practice is to combine the FACT with the NAPL Flute cover to map both the NAPL and the distribution of the dissolved phase. See the Model 405 FACT Flute Data Sheet for more information.

Sampling NAPL Layers

Solinst offers the Model 425 Discrete Interval Sampler, which can be used to sample the NAPL layers once a NAPL Flute is removed. The Discrete Interval Sampler is a stainless steel sampler, with LDPE tubing mounted on a convenient Solinst reel.

The reel has a pressure attachment for a high pressure hand pump, and a pressure/vent switch which is used to apply and release the pressure on the sampler.

Solinst also offers the Model 425-D Deep Sampling Discrete Interval Sampler for obtaining samples from submerged depths as much as 1200 m (4000 ft).

Related Products

Enhanced Bioremediation

The Waterloo Emitter™is a simple, low cost device designed for the bioremediation of contaminated groundwater. It enables oxygen or other amendments to diffuse through silicone or LDPE tubing in a controlled, uniform manner. Ideal for aerobic bioremediation of MTBE and BTEX, with minimal maintenance required.

3/8" Diameter Flexible Pneumatic Pump

The Micro Double Valve Pump has a remarkably small and flexible design. At 3/8" (10 mm) diameter it is small enough to sample groundwater from channels of a CMT System.

Rugged Peristaltic Pump

Compact, lightweight, and water-resistant, the Solinst Peristaltic Pump is designed for field use. One easy-access control allows various speeds and reversible flow. Ideal for shallow water and vapor sampling.

Tag Line - Rugged, Simple, Convenient

The Tag Line uses a weight attached to laser marked cable, mounted on a sturdy reel. Convenient for measuring depths during monitoring well construction.