Packer Tests & Hydrogeological Characterization

Estimating aquifer properties, such as hydraulic conductivity (K) and permeability is an essential part of site characterization and creating accurate conceptual site models during site investigations. The data gained through aquifer characterizations help to plan further monitoring programs and remediation efforts.

Packer Tests are a great way to obtain these aquifer characteristics using minimal equipment that is readily available and at a reasonable cost. They are also relatively simple to set up and perform – most requiring just one person.

Packer Tests can be performed at multiple, isolated depth discrete zones in a single borehole or monitoring well, providing data to create a hydraulic conductivity profile. Performing tests in boreholes across a whole site can help interpret the stratigraphic profile and provide additional information beneficial to understanding the entire conceptual site model.

What is a Slug Test?

Slug Tests are one of the most simple Packer Tests that can be performed. In general, Slug Tests artificially raise or lower the water level from its normal static level by adding or removing a known volume. Water level data during the recovery to static is recorded and used to calculate aquifer characteristics.

Slug Tests are ideal in environments with lower hydraulic conductivity, where long-term pumping tests are not feasible, or where budgets are smaller.

Conducting a Falling Head K Test

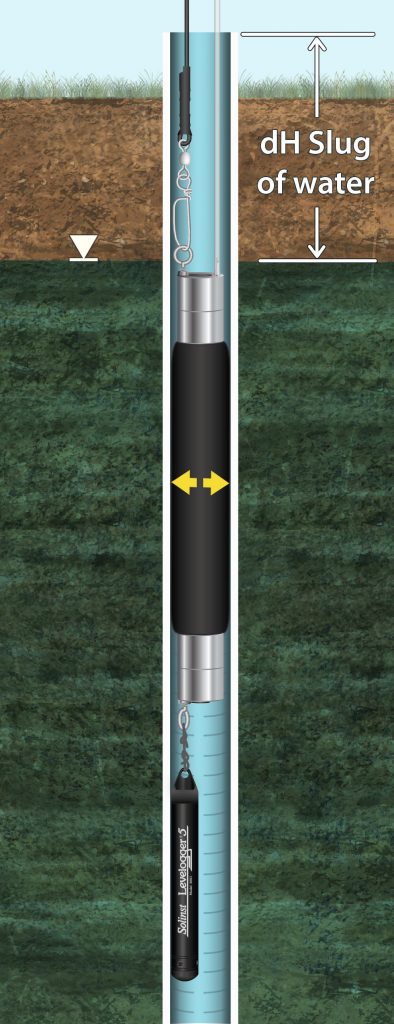

Solinst Model 800 and 800M Low Pressure Pneumatic Packers are ideal for performing various types of borehole and well tests, including Falling Head K Tests. The illustration shows how a 1.8″ (46 mm) diameter Solinst 800 Single Packer can be set up for this test.

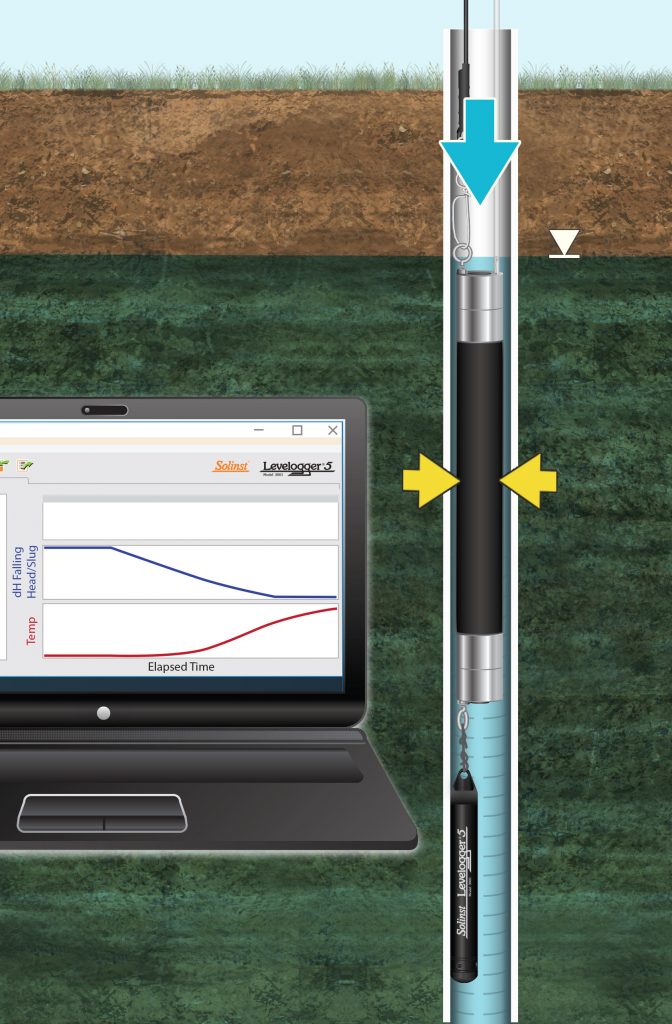

Solinst Packers have eyebolts, top and bottom, for connecting monitoring instruments such as dataloggers. In this case, a Solinst Levelogger is connected to the eyebolt on the bottom of the Packer and set to record water level readings at a high frequency. Logarithmic style sampling can also be programmed using the scheduled sampling option in Solinst Levelogger Software.

In this example, the depth to static water level is measured, and then the Packer is lowered on a suspension cable (e.g. 103 Tag Line) down the 2″ (50 mm) OD monitoring well to just below the water level, and above the screen inlet. The Packer is then inflated to 40 psi (275 kPa).

A known volume of potable water is added to the top of the well. This height of water represents the change in head (dH) waiting to be released. Then the Packer is instantaneously vented, supplying a known volume, or slug, of water to the monitored zone. The Levelogger records the changes in water level as the well recovers back to static level.

This type of test can also be performed using a Straddle Packer setup, and in larger boreholes using the Solinst 3.9″ (99 mm) OD Low Pressure Pneumatic Packers.

To discuss how Solinst Pneumatic Packers can be used in your next groundwater monitoring project, contact one of our Technical Sales Representatives. If you already know Packers will work for you, Get a Quote!