Peristaltic Pump Operating Instructions

IMPORTANT

- The pump should be operated in an upright position, sitting on the rubber feet on the bottom of the pump (handle and dial on top).

- Pump is water resistant but not waterproof. Do not submerge in water.

- Pump is not designed for long-term continuous uninterrupted use.

- To avoid motor damage due to over-heating, allow pump to cool fully at least every 7–8 hours, or more often under high ambient heat conditions.

- Pumping rates will decrease with elevation, and as the amount of lift increases.

- Replace the tubing regularly. Worn tubing can cause the pump to be inefficient. This will show as a limited ability to lift water. If the tubing looks worn, flattened or cracked, replace the tubing.

- If used in cold weather, ensure that there is no ice in the tubing before starting the pump.

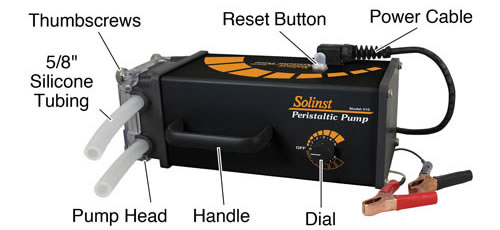

Solinst Model 410 Peristaltic Pump (#112981)

Power Requirements for Solinst Peristaltic Pumps

The pump operates from an external 12V DC power supply such as a car, truck or marine 12 volt battery that can supply at least 3–5 amps at maximum draw. The pump has a 3 m (10 ft) power cable with connector clips for direct battery connection.

For more portable, short duration sampling events, attach the optional 12V Battery Holder (see separate instructions).

The power cable clips are oversized for use with automotive batteries. The red clip connects to the positive (+) battery terminal, black to negative (-) battery terminal. If the battery is connected with reverse polarity the pump will not be harmed, but it will NOT operate until the polarity is connected correctly.

A circuit breaker reset button is located on the side of the pump. In the event the pump amperage exceeds 10 amps, the circuit breaker will trip (button pops out) and turn the pump off. To reset the breaker, simply press the reset button back in to regain operation of the pump.

If the pump is to be powered by a typical 45Ah vehicle battery for more than 3 continuous hours, start vehicle and run for 15 minutes to recharge the battery.

Operation

- The Solinst Peristaltic Pump has an integral forward/reverse, variable flow dial with an OFF position, which has a central detent. When turning the unit OFF, ensure you feel the dial snap into position.

- The pump should always be kept with the control in the OFF position when it is being attached to a power source or stored.

- Once attached to a power source, turn the dial in the direction required and adjust the flow as desired.

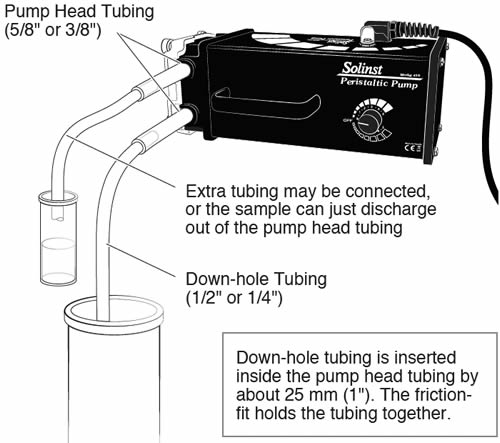

- The standard 5/8" (16 mm) OD medical grade silicone tubing can be attached to 1/2" (13 mm) OD down-hole sample tubing and gives sample rates up to 3.2 L/min.

- The 3/8" (10 mm) OD silicone tubing and adaptor kit allows the use of 1/4" (6 mm) OD down-hole sample tubing, giving sampling rates as low as 40 mL/min.

- Ensure that the chosen silicone tubing has been properly installed in the pump head.

- Connect one end of the silicone tubing to the down-hole sample line. See diagram below.

- Either connect the other end of the silicone tubing to a discharge tube, or simply discharge out of this end of the tubing. See diagram below.

- Connect the negative (black) battery clip to the negative terminal post on a 12V DC battery and the positive (red) battery clip to the positive terminal.

- Turn the dial in the direction required and adjust the flow as desired.

Solinst Model 410 Peristaltic Pump Setup

| Down-hole Tubing Specifications | |

|---|---|

| Use with Standard 5/8" OD Silicon Tubing | |

| 1/2" OD x 3/8" ID LDPE (100 ft coil) | 109490 |

| 1/2" OD x 3/8" ID LDPE (250 ft coil) | 109489 |

| 1/2" OD x 3/8" ID LDPE (500 ft coil) | 109488 |

| Use with Optional 3/8" OD (with Adaptor Kit) Silicon Tubing | |

| 1/4" OD x 0.17" ID LDPE Tubing (100 ft coil) | 109465 |

| 1/4" OD x 0.17" ID LDPE Tubing (250 ft coil) | 109464 |

| 1/4" OD x 0.17" ID LDPE Tubing (500 ft coil) | 109463 |

| 1/4" OD x 0.17" ID PTFE-lined LDPE Tubing (100 ft coil) | 109454 |

| 1/4" OD x 0.17" ID PTFE-lined LDPE Tubing (250 ft coil) | 109444 |