Decontamination

Note:

- Always follow your local guidelines and standard protocols.

- Do not use acetone on the O-rings.

- Completely disassemble the Pump. See Disassembly section.

- Wash all pump components with phosphate-free soap or a detergent.

- Rinse all components thoroughly with deionized water.

- Replace any worn O-rings and Bladder if necessary,and reassemble. We recommend replacing Bladders between wells, or as needed.

Disassembly

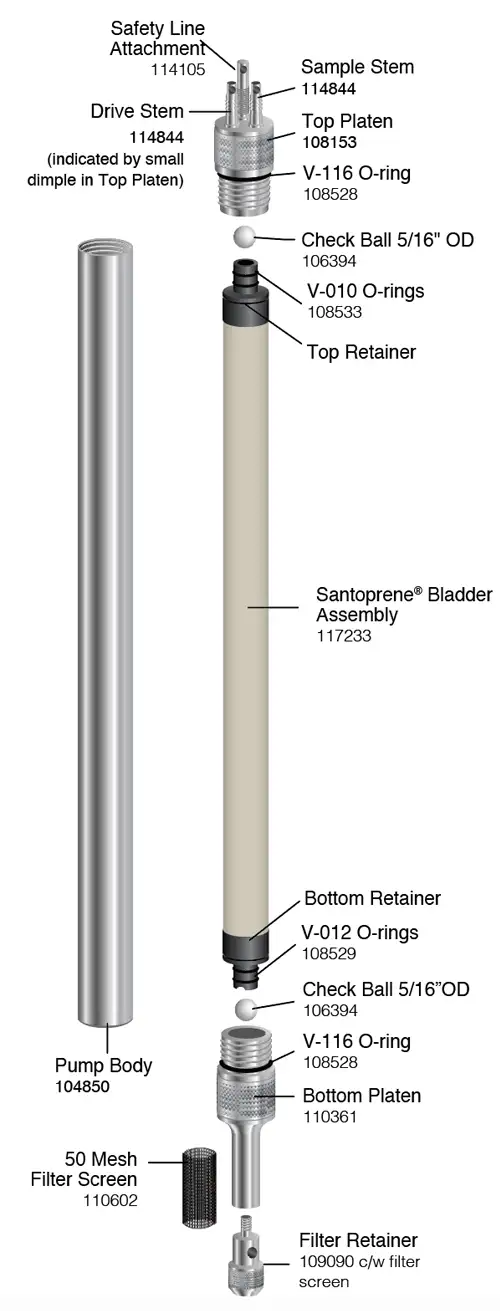

- Unscrew and remove the Filter Retainer, Filter Screen and Top and Bottom Platens, being careful not to lose the Check Balls.

- Remove the Bladder Cartridge Assembly from the Pump Body.

Reassembly

- If necessary install new O-rings on both Top and Bottom Retainers and both Platens. (Total of 6).

- Put the Filter Screen over the Filter Retainer. Screw the Filter Retainer into the Bottom Platen.

- Drop the 5/16" OD PTFE Check Ball into the Bottom Platen. Do not force the ball in, as the correct ball should drop in easily.

- Fit the Bottom Retainer of the Bladder Cartridge Assembly firmly into the Bottom Platen. (Bottom Retainer has a notched end).

- Slip the Pump Body over the Bladder Cartridge Assembly and screw it onto the Bottom Platen.

- Drop a 5/16" OD PTFE Check Ball into the Top Platen and screw the Pump Body onto it.

- Shake the assembled pump to hear if the Check Balls rattle. If not, repeat the steps to ensure that the Check Balls are positioned correctly.

Note:

The 1" Mk2 Bladder Pumps are also available with 316 stainless steel check balls, and are operated and assembled in the same manner.