Figure 10-2

Solinst 2" Locking Well Cap

for Wireline or Kevlar Cord

When installing on a suspension wire or cord, the Levelogger is pre-programmed and started using the software. It is then deployed with the suspension wire or cord connected to the installation cap of the Levelogger to the underside of a well cap.

The data is retrieved manually, by withdrawing the Levelogger, removing the installation cap and attaching a Field Reader 5 or Desktop Reader 5 (see Section 2). This type of installation is applicable to both submerged and barometric applications.

Note:

There is also the option to communicate with a DataGrabber 5 or Levelogger 5 App Interface (see separate User Guides).

Before deployment, to ensure a water-tight seal, tighten the installation cap onto the Levelogger until there is no green o-ring visible.

Figure 10-3 Proper Installation Cap Connection

Note:

The o-ring on the optical end of the Levelogger should be inspected regularly and replaced as required. See Section 10.2.

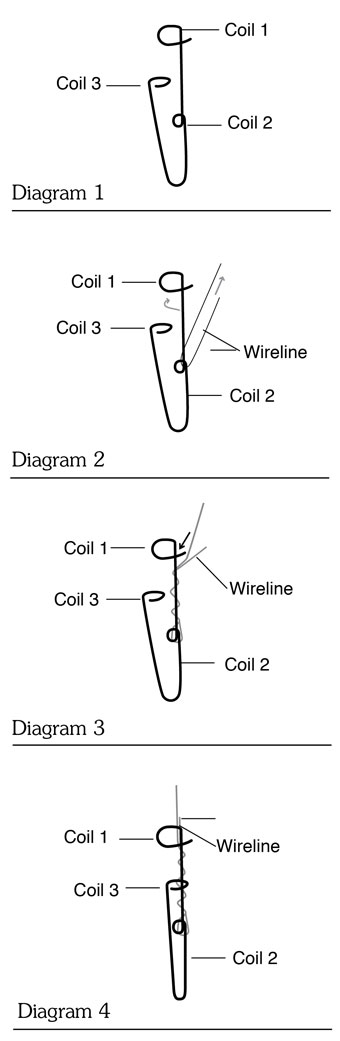

Figure 10-4

Wireline Hook Installation

Solinst supplies stainless steel suspension wire assemblies including SS stranded wire and hooks available in a variety of lengths from 50 ft (15 m) to 500 ft (150 m), and Kevlar cord assemblies to 500 ft (150 m). Solinst also supplies the Model 3001 2" Well Cap Assembly from which the Levelogger can be suspended. An Adaptor for 4" wells also available (see Section 10.1.1.3).

Follow these steps to install the Levelogger using stainless steel wire and hooks:

- Loop the cable through the coil 2 of the hook assembly, then wind the looped strands several times around the hook shaft and pass through coil 1.

- Pass coil 3 through the Well Cap eyelet or Levelogger/Barologger eyelet and snap coil 3 to the hook shaft.

- If the Well Cap is not used then some secure tie-off point should be used or installed.

- If installing a Barologger, ensure the suspension level is above the highest expected water level.

- When retrieving data and/or reprogramming the Levelogger, extract it from the monitoring location, un-thread the installation cap, interrogate and re-suspend the unit rechecking the security of the wireline clamps each time.

The wireline is a multi-stranded 304 Stainless Steel wire with a break strength of about 40 lbs.

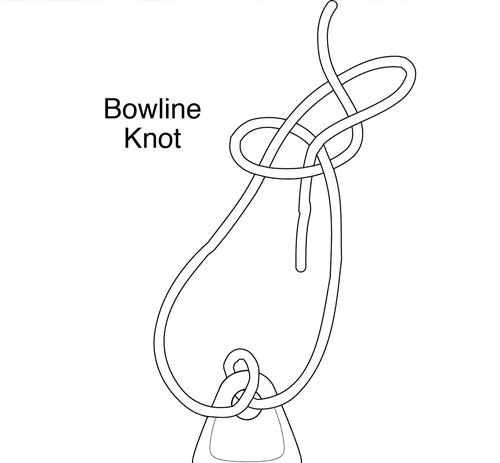

Figure 10-5 Kevlar Cord

Figure 10-6 Bowline Knot Used to Connect Kevlar Cord to the Levelogger

It is recommended that the Kevlar cord be connected to the Levelogger and well cap using a bowline knot (see Figure 10-6). The Kevlar cord is comprised of multiple Kevlar strands braided with black polyester, and has break strength of 150 lbs. Kevlar is very suitable for underwater applications in freshwater and marine environments, as the material resists rusting.